In the past, the rule of thumb was that no more CDs should be produced per day, as the system can hold media in the magazines. With more professional robots and printers, the production volume has shifted up a little and is usually determined by the number of recorders. With 100 CDs per day and 200 working days per year, the system should already have at least 2 recorders, because otherwise you can already guess that with the MTBF of a recorder of 15,000-17,000 discs, the system has to go to the workshop or be repaired annually. From 300 patients per day, a second system should be considered, which also provides a practical redundancy for recorder failures and other defects.

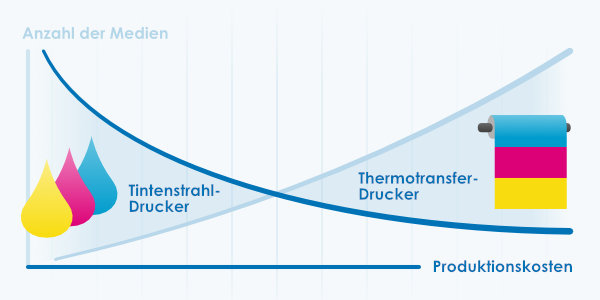

A further point of calculation is the printing of the media. While the differences in printing costs between ink (Epson or Rimage) and thermal transfer (Everest, Encore) are rather marginal and the decision to use one or the other system is more for aesthetic reasons, thermal transfer printing (Prism) offers an immense price difference with only a few cents printing cost. Since no special printable medium is required here, media can be pre-printed and then only the patient data is printed in the practice. On the one hand, this takes only a few seconds and shortens production times and on the other hand offers cost advantages of up to 20 cents or more per medium. The additional costs of the system can be run in from 200 patients per day within 1-2 years and then offer a tangible cost advantage.

Maintenance of the large devices is also somewhat easier. While the small and compact systems usually have to be completely disassembled due to their design, the larger Producer Systems, due to their modular construction, can be easily replaced on site. Due to the use of industrial components (much metal, little plastic) these systems are suitable for 24/7 operation anyway and offer much longer maintenance cycles.

If not all systems are supported by the PACS manufacturers, INCOM still offers solutions via DICOM interfaces to integrate any desired system into almost any network.